Researchers make progress in low-temperature sintered microwave dielectric ceramic materials

Nov 22, 2022

With the development of 5G/6G communication, microwave dielectric ceramic materials with low dielectric loss are urgently needed to ensure effective signal transmission. At the same time, in order to adapt to the rapid growth of portable devices, the miniaturization and multifunction of electronic devices have become extremely important.

Low-temperature co-fired ceramics (LTCC) technology can achieve high-density packaging of large-scale integrated (LSI) components and hybrid integration of active and passive components. It is a key technology to achieving miniaturization and multifunction of electronic devices. In LTCC technology, microwave dielectric ceramic materials and Ag electrodes are co-fired. Microwave dielectric ceramic materials must be sintered at a temperature lower than the melting point of the Ag electrode. Additionally, there should be no reaction between ceramics and Ag electrodes. As packaging materials, high thermal conductivity can effectively improve the system’s stability. Therefore, it is of great significance to prepare microwave dielectric ceramics having low sintering temperature, low dielectric loss, good chemical compatibility with Ag, and high thermal conductivity.

Chair Professor Hong Wang’s research group from the Department of Materials Science and Engineering at the Southern University of Science and Technology (SUSTech) has recently made progress in low-temperature sintered microwave dielectric ceramic materials.

Their related paper, entitled “Low temperature sintered MgO–based microwave dielectric ceramics with ultra-low loss and high thermal conductivity,” was published in the Journal of the American Ceramic Society, a leading journal in the field of ceramic materials.

Prof. Wang’s team chose the binary eutectic fluoride 0.2SrF2-0.8LiF (abbreviated as S2L8) as the sintering aid to reduce the sintering temperature of MgO ceramic. MgO-x wt.%S2L8, (x=5,7,10) ceramics were prepared by the solid-state reaction method. Combining the low dielectric loss and high thermal conductivity of MgO, the good microwave dielectric properties of fluorides, and the low melting point of sintering aid, the obtained MgO-based microwave dielectric ceramics have low sintering temperature, high thermal conductivity, and ultra-low dielectric loss (corresponding to high-quality factor) in the high-frequency band.

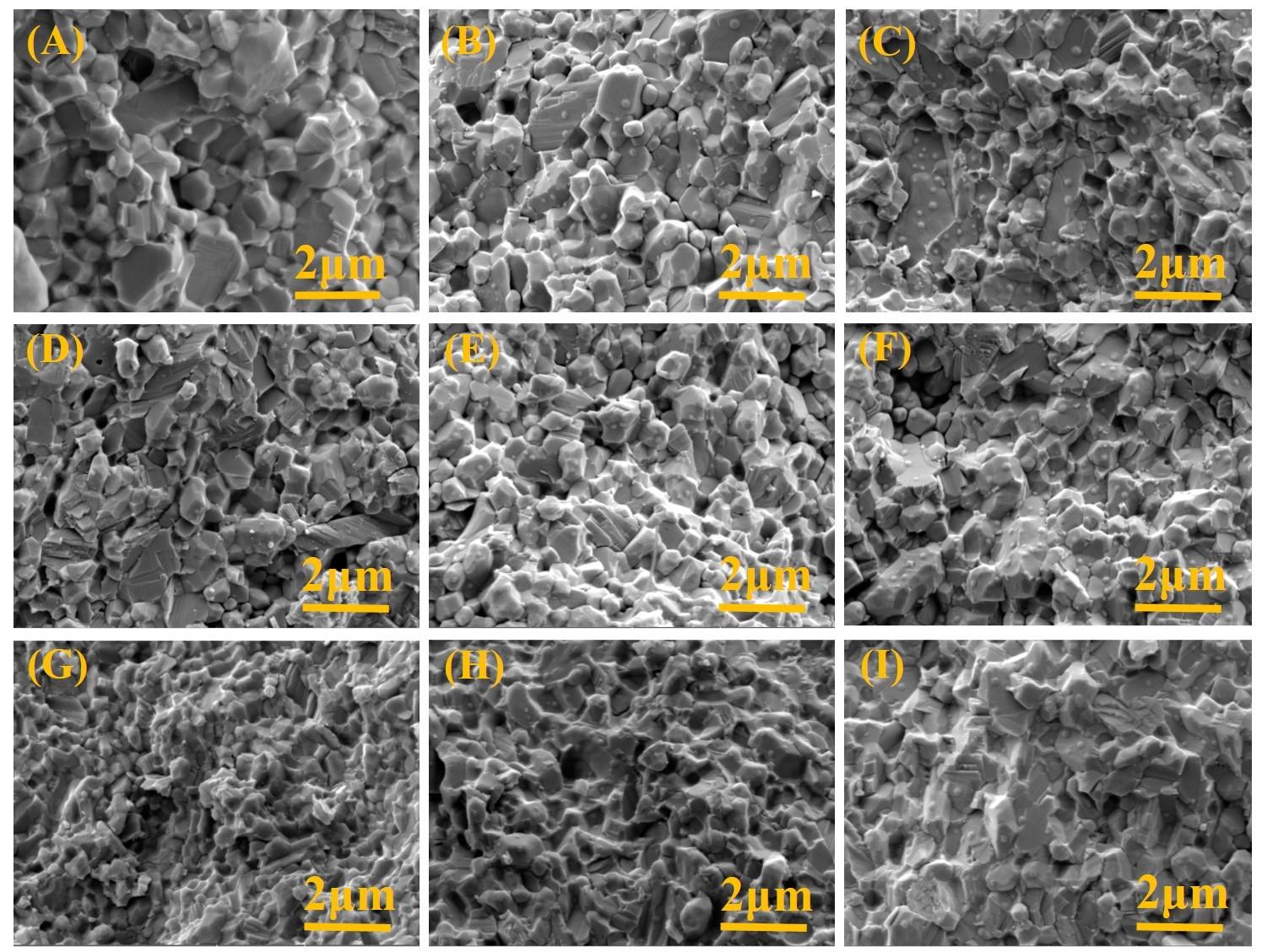

As shown in the SEM images of fracture surfaces of MgO–x wt.%S2L8, (x=5,7,10), ceramics are densified during the sintering process. The number and pore diameter of the pores are significantly reduced. At the same time, the grain size and grain morphology of ceramics vary with different sintering temperatures.

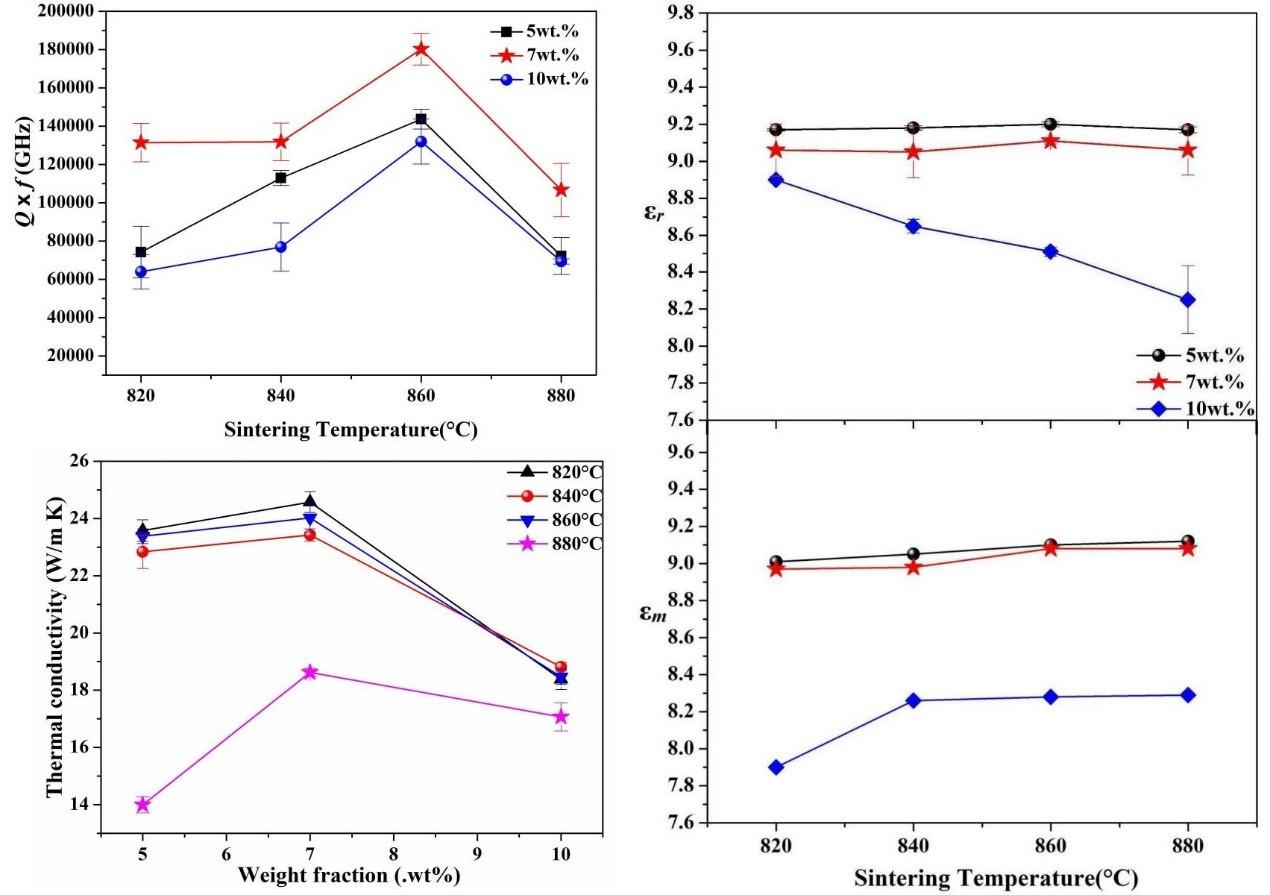

In this study, the researchers discussed how the relative density and microstructure of ceramics affect microwave dielectric properties, and analyzed the relationship between properties and structure.

Figure 1. SEM images of fracture surfaces of MgO–x wt.%S2L8, (x=5,7,10) ceramics

MgO–7wt.% S2L8 ceramic sintered at 860℃ in this study shows excellent microwave dielectric properties of εr =9.11 and τf = -40.33 ppm/°C. More importantly, it has a high Q × f value of 180233 GHz, corresponding to an ultra-low dielectric loss of 6.83×10-5 at 12.31 GHz. It also has a high thermal conductivity of 24.02 W/(m K). Combining both the XRD pattern and BSE image of the Ag-doped ceramic sample, it can be concluded that there is no chemical reaction between ceramic and Ag.

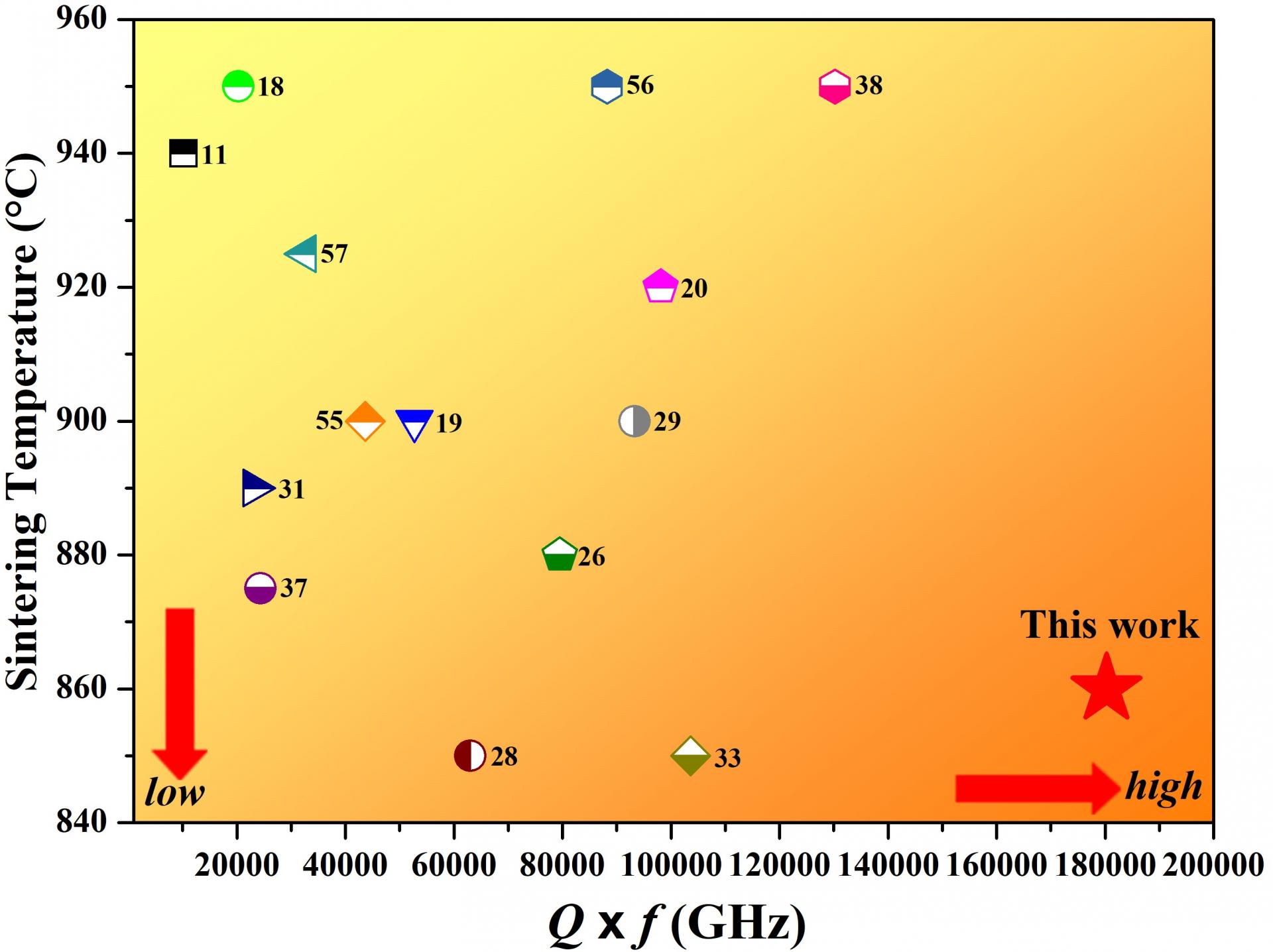

The ceramics obtained in this work have good chemical compatibility with the Ag. Compared with some ceramics reported in previous works, MgO–7wt.% S2L8 ceramic sintered at 860 ℃ has a lower sintering temperature and higher quality factor. The MgO-based ceramics in this study exhibit great properties of low sintering temperature, ultra-low dielectric loss at a high-frequency range, high thermal conductivity, and good chemical compatibility with Ag. This series of MgO-based ceramics are promising candidates as low-loss LTCC materials for 5G/6G applications.

Figure 2. Properties of MgO–x wt.%S2L8, (x=5,7,10) ceramics: Q × f value, relative dielectric constant and thermal conductivity

Figure 3. (A) XRD pattern of Ag-doped ceramic sample, (B) BSE image of Ag-doped ceramic sample

Figure 4. Optimum sintering temperatures and the Q × f values of ceramics obtained in previous works and this work.

Binfeng Zhao, a doctoral candidate of Prof. Hong Wang’s research group, is the first author of this paper. Prof. Hong Wang is the corresponding author. Xianqiang Chen, Naichao Chen, Xu Xinwei, Yanni Lu, and Jin Cheng in Prof. Wang’s group also made important contributions to this work.

This research was supported by the Department of Science and Technology of Guangdong Province and the Science, Technology and Innovation Commission of Shenzhen Municipality.

Paper link:

Latest News

Related News