Researchers analyze characteristic parameters of droplet spin coating process

Nov 30, 2022

Spin coating is a film formation method in which the liquid on the substrate is spread out by centrifugal force to form a thin film. Due to its good uniformity, repeatability, and high performance of the device, the spinning coating process is widely used in the fields of photoresist coating, organic photovoltaic cells, perovskite photovoltaic cells, and so on.

In spin coating, a small volume of coating material is dispensed onto a substrate, which is either already spinning (dynamic) or subsequently set to spin (static). Dynamic spin coating is often preferred because it requires less coating material than its static counterpart. Moreover, for coating of multiple layers, the dynamic spin coating reduces the re-dissolving of the previous layer if the solvents are not strictly orthogonal.

Dynamic spin coating is often preferred because it requires less coating material than its static counterpart. For example, on a typical one-centimeter square substrate, static spin coating requires tens of microliters of solution, while dynamic spin coating requires only about six microliters. In addition, dynamic spin coating involves the process of droplets hitting the rotating substrate, whose inertial impact can complete the initial spread and be used at lower speeds. Spin coating is also a classic research topic in fluid mechanics. However, the majority of prior works have focused on static dispensing, where the inertial effect of the landing drop on the spinning substrate is excluded.

Professor Weiwei Deng’s team from the Department of Mechanics and Aerospace Engineering at the Southern University of Science and Technology (SUSTech) has recently published their findings on the droplet spin coating process. By combining experimental observation, numerical simulation, and theoretical analysis, the team quantitatively analyzed the characteristic parameters such as spreading radius, liquid film thickness, and contact line velocity in different stages of ethanol droplet spin coating process.

Their paper, entitled “On axisymmetric dynamic spin coating with a single drop of ethanol,” was published in the Journal of Fluid Mechanics, a top scientific journal in the field of fluid mechanics.

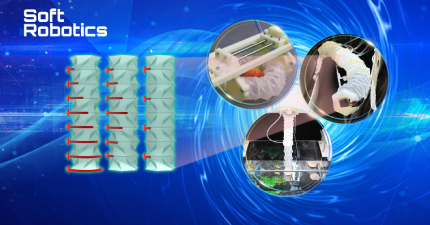

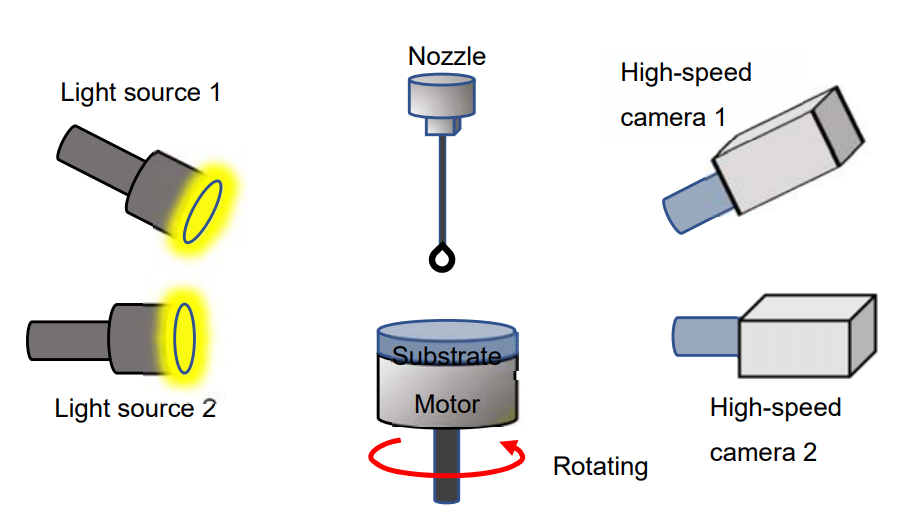

Figure 1. Schematic of experimental configuration of dynamic spin coating

The liquid film was observed from different angles (from 45° and side view) using two high-speed cameras (Figure 1). The video shows (Figure 2a) that the liquid film contains two regions: a smooth film area in the middle and a capillary ridge raised on the edge. In order to measure the thickness of liquid film during dynamic spin coating, a fluorescence imaging method was designed. By mixing a fluorescent dye (Rhodamine 6G) with alcohol and irradiating it with uniform ultraviolet light, the film thickness distribution of each frame can be obtained from the brightness in the video according to Lambert’s law and the calibration of the known film thickness.

This method can be used to resolve liquid film of several microns and capillary ridge of 100 microns from high-speed video (Figure 2b). The experimental measurement and numerical simulation results are in good agreement (Figure 3).

Figure 2. (a) Spread radius and capillary ridge width of 45°and side view; (b) Measurement of liquid film thickness by fluorescence method based on Rhodamine 6G alcohol solution; (c) The droplet spread profile obtained after image processing of fluorescence imaging

Figure 3. Comparison of a spreading ethanol drop shape obtained from experimental images and simulation results

For droplet impact on static substrate, the Weber number (We) is defined as the ratio between the inertia and surface tension forces, and describes the relative importance between inertia and capillary action. In the process of dynamic spin coating, the Weber number picture also plays an important role, but mainly in the stage of inertia spreading. In the centrifugal spreading stage, since the characteristic pressure generated by the centrifugal acceleration is the ρω2R2 (R is the spreading radius of the liquid film) and the capillary pressure is ~γ/h (h is the thickness of the liquid film), the rotating bond number Bor can be defined as the ratio of two quantities Bor = ρω2V/γ, and V is the volume of the droplet.

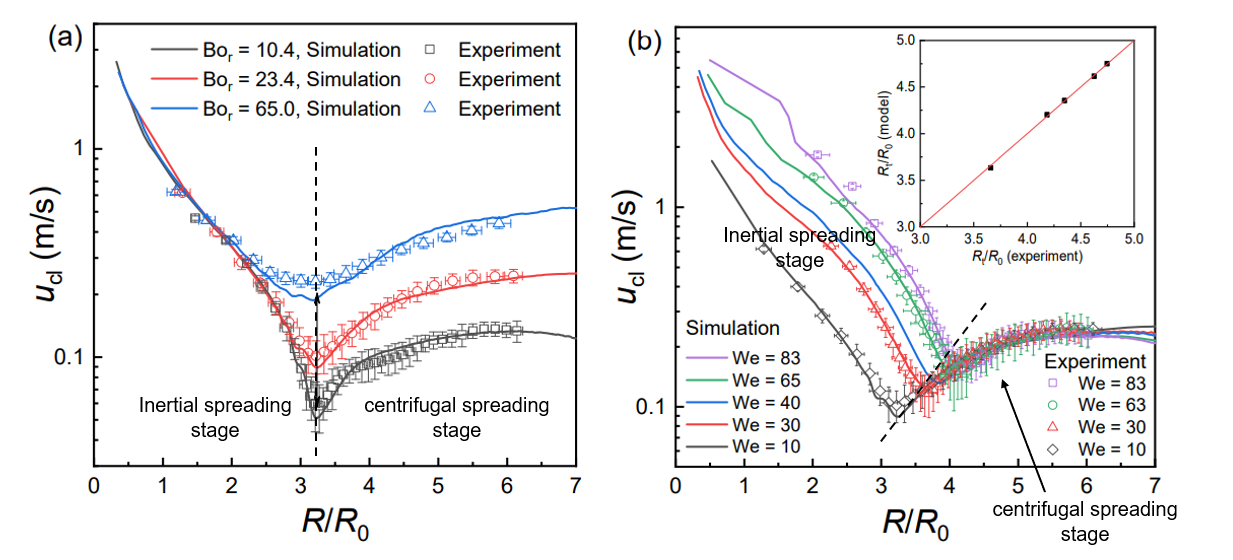

The liquid film’s characteristic parameters (spreading radius, film thickness, capillary ridge characteristics, contact Angle) were systematically observed and analyzed in different We and Bor conditions. It found that droplet spreading in the dynamic spin coating process can be divided into two stages: the inertial spreading stage and the centrifugal thinning stage. The dividing point of the two stages is the lowest droplet spreading speed.

In the inertial spreading stage, the kinetic energy and surface energy converted from the gravitational potential energy of the droplet account for a large part of the total energy of the droplet. The droplet spreading still follows the law of the droplet hitting the stationary base; that is, the spreading radius increases exponentially with the time by a power of 1/2.

In the centrifugal thinning stage, the radius increases exponentially with the time by a power of 1.2; that is, the droplet spread speed slowly accelerates at this stage. At the same time, the film thickness and time satisfy the power exponential rule of -1/2, which takes into account the influence of air shear force and is consistent with the conclusion based on lubrication theory. It also found that the transient radius between the two stages, i.e., the spreading radius at the lowest spreading velocity, is independent of the number of rotating bonds (Figure 4a), but is approximately a power of 1/10 with the We (Figure 4b).

Figure 4. Radial spreading velocity (contact line moving velocity) plotted against the dimensionless spreading radius at different (a) Bond number and (b) We number

Yuming Pan, an undergraduate student at SUSTech, is the first author of this paper. Prof. Weiwei Deng and Research Asst. Prof. Huihui Xia are the co-corresponding authors.

This work was supported by the National Natural Science Foundation of China (NSFC) and the Science, Technology and Innovation Commission of Shenzhen Municipality.

Paper link:

Latest News

Related News