Progress in application of gel-based i-TE materials and devices in wearable self-powered devices

Mar 23, 2022

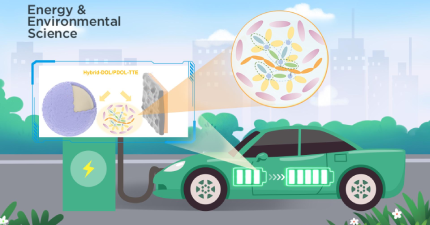

Thermoelectric materials, as a kind of green energy material that can convert “heat energy” into “electricity” without external force, can use the ubiquitous environmental heat energy to provide continuous power supply for small sensors or electronic devices in the Internet of Things (IoT) system.

Ionic thermoelectric materials (i-TE) use ions as energy carriers, and the thermopower can reach the order of mV K-1 based on the Thermodiffusion Effect or the Thermogalvanic Effect. At present, the optimized thermopower (or Seebeck coefficient) of electronic thermoelectric materials (e-TE) is about 200 μV K-1. The low thermopower can hardly meet the power supply demand of various sensors in the IoT system.

Associate Professor Weishu Liu’s research group from the Department of Materials Science and Engineering (MSE) has recently made important progress in gelatin-based quasi-solid i-TE materials. Their study provides a promising approach to developing reliable and green power sources for IoT sensors near room temperature.

Their relevant results, entitled “3D Hierarchical Electrodes Boosting Ultrahigh Power Output for Gelatin-KCl-FeCN4−/3− Ionic Thermoelectric Cells,” were published as the cover article in Advanced Energy Materials.

Prof. Liu’s group previously reported a gelatin-based i-TE material (Gel-KCl-FeCN4-/3-) in Science, which combines two ionic Thermoelectric effects to obtain a giant thermopower of 17 mV K-1 (Science 368, 1091–1098 (2020)). This work has attracted extensive attention in the academic world. This gelatin-based material has achieved an order of magnitude enhancement in output power density compared with previously reported quasi-solid i-TE materials. However, compared with electronic thermoelectric devices, the output power of i-TE devices is still lower. The reason is that the low ionic conductivity leads to the high internal resistance of the device, which affects its application range.

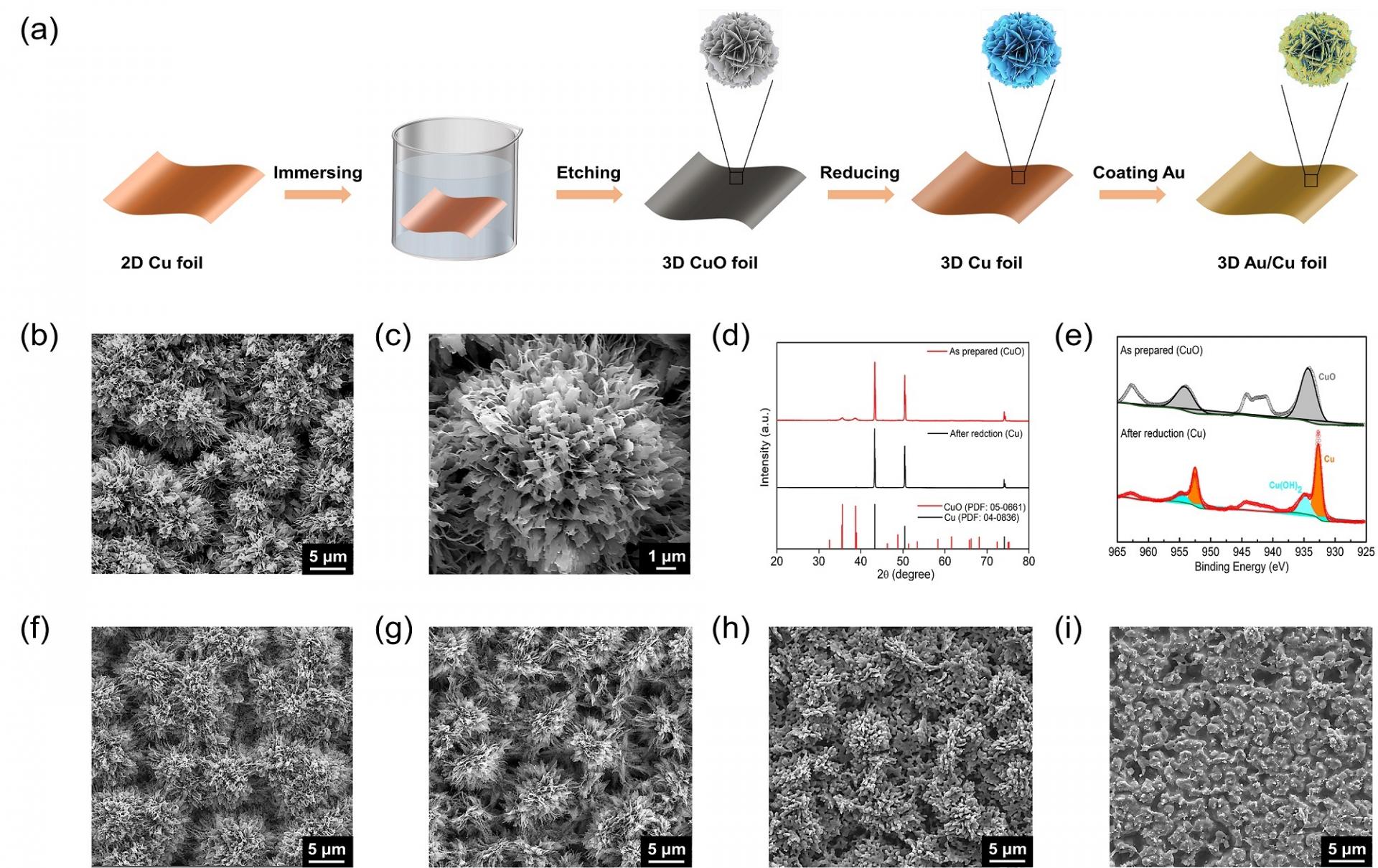

In this study, the researchers aimed to increase the output power of the i-TE device by increasing the electrode’s surface roughness. The design of the three-dimensional (3D) microflower gold/copper (Au/Cu) electrode greatly improves the gelatin-based i-TE device output power density. Figure 1 shows the preparation process of the 3D Au/Cu electrode. The 3D Au/Cu electrode materials with different surface structures were prepared by changing the reduction temperature (TRe). With the increase of reduction temperature, the surface morphology gradually changed from microflower structure (TRe = 300 ℃) to nanorods structure (TRe = 500 ℃) and even two-dimensional structure (TRe = 600 ℃).

Figure 1. Preparation and characterization of 3D hierarchical Au/Cu foils. (a) Schematic illustration showing the preparation process of the 3D Au/Cu foil from 2D Cu foil. (b & c) SEM images of as-fabricated microflower CuO foil. (d) XRD patterns. (e) High-resolution XPS spectrums of as-fabricated CuO and reduced Cu foils at 300 °C. The SEM images of 3D hierarchical Au/Cu foil at different reduction temperatures of (f) 300 °C, (g) 400 °C, (h) 500 °C, and (i) 600 °C, respectively.

The surface roughness value (RF) of electrode materials was defined by using a double-layer capacitance test method. It also found that the coating of gold particles can effectively avoid the corrosion of copper electrodes. The power density and energy density in this work are 8.9 mW m-2 k-2 and 80 J m-2, respectively, which are greatly improved compared with the previous work and are the highest values in this field. The cumulative output energy density of the device is 416 J m-2 in a week, with an average output energy density of 59.4 J m-2 per day, showing excellent long-time discharge characteristics.

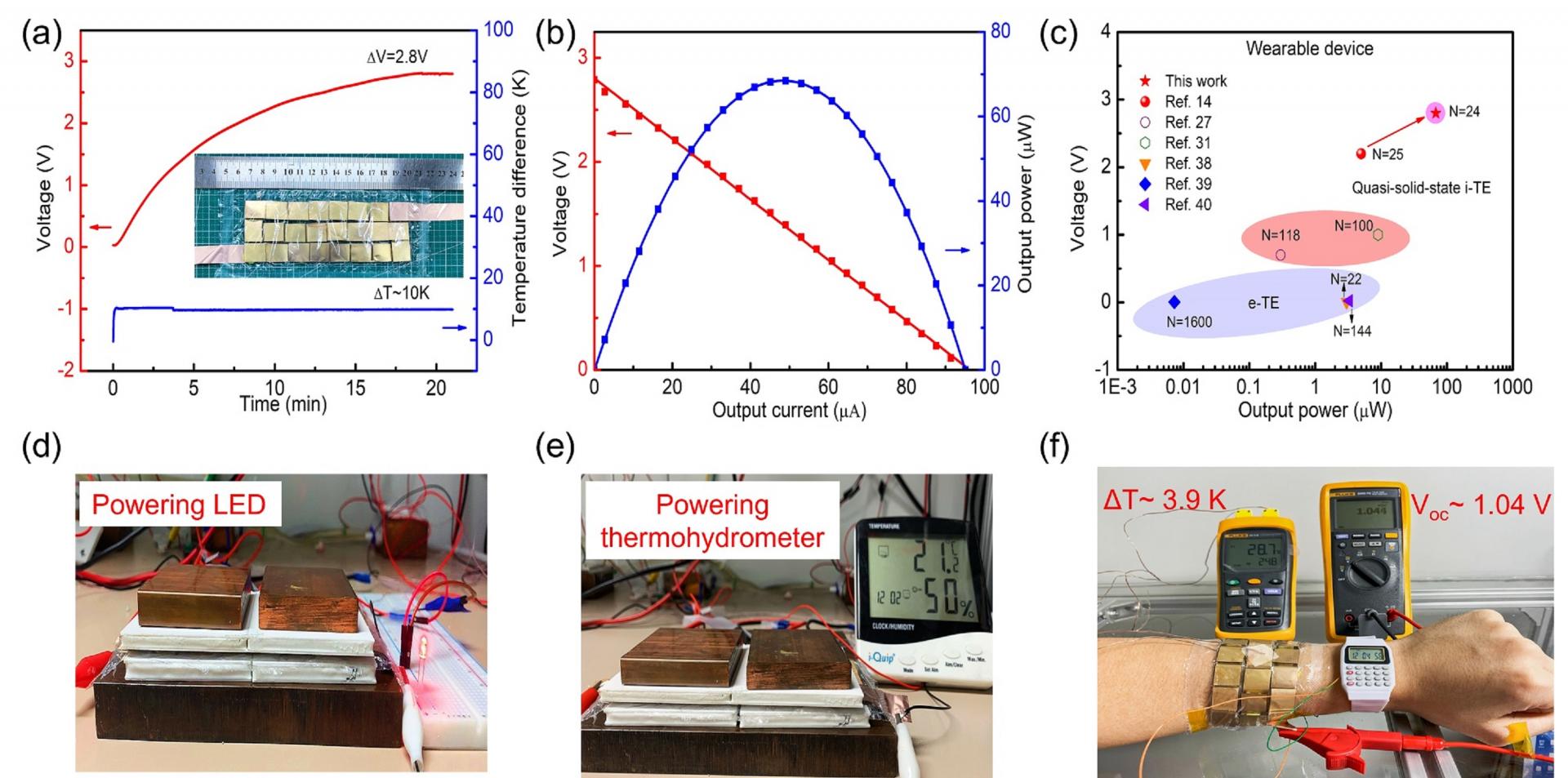

Figure 2 shows a watch-strap-styled integrated device consisting of 24 i-TE units in series. The wearable i-TE device can generate remarkable voltage and power values of 2.8 V and 68 μW, respectively, with a temperature difference (10 K) from being worn on the arm of a human being. The device can directly drive various electronic products, including the LED bulb, the thermohydrometer, and electronic watches without additional voltage boosters. Compared with the reported e-TE and i-TE wearable devices, this work’s output voltage and power have obvious advantages.

Figure 2. Wearable i-TE device. (a) Voltage generated from the i-TE wearable device with 24 i-TE cells in series worn on the human arm in a cold environment (ΔT of ~10 K). (b) Voltage and output power versus output current of the flexible i-TE wearable device by harvesting real body heat. (c) Performance comparison in output voltage and power of the e-TE and quasi-solid-state i-TE wearable device worn on a real human body. (d) LED bulb. (e) A thermohydrometer using heating plates (ΔT of 10 K). (f) Digital watch by harvesting human body heat (ΔT of ~3.9 K).

In this study, two working modes of i-TE devices were clarified, and several evaluation parameters of discharge characteristics were proposed, including instantaneous power density, engineering power density, and long-time output energy density. The normalized instantaneous power density and energy density achieved in this research are the maximum values in this field. In addition, the optimized wearable i-TE device harvests temperature differences near room temperature from the human body to light up a variety of electronic devices without a booster. This work is expected to promote the application of gel-based i-TE materials and devices in wearable self-powered devices.

Yuchen Li, a Ph.D. student from the Department of MSE at SUSTech, is the first author of this paper. Prof. Weishu Liu is the corresponding author.

The project was supported by the Guangdong Innovative and Entrepreneurial Research Team Program, Shenzhen Science Technology Fund, and the Tencent Foundation through the Xplorer Prize.

Paper link: https://onlinelibrary.wiley.com/doi/full/10.1002/aenm.202103666

Latest News

Related News