New strategy for super stable e-skin design by SUSTech researchers

Mar 21, 2022

Electronic skins (e-skins) are devices that can respond to mechanical stimuli and convert mechanical information to digital signals. A great challenge for existing e-skins is that they may easily fail under extreme mechanical conditions due to their multilayered architecture with mechanical mismatch and weak adhesion between the interlayers.

Professor Chuanfei Guo’s team from the Department of Materials Science and Engineering at the Southern University of Science and Technology (SUSTech) has recently proposed a design strategy for superstable e-skins with a quasi-homogeneous composition for all interlayers and introducing interlinked and microstructured interfaces in a multilayered sensor.

Their research, entitled “Highly stable flexible pressure sensors with a quasi-homogeneous composition and interlinked interfaces,” has been published in Nature Communications, a multidisciplinary journal that covers the natural sciences, including physics, chemistry, earth sciences, medicine, and biology.

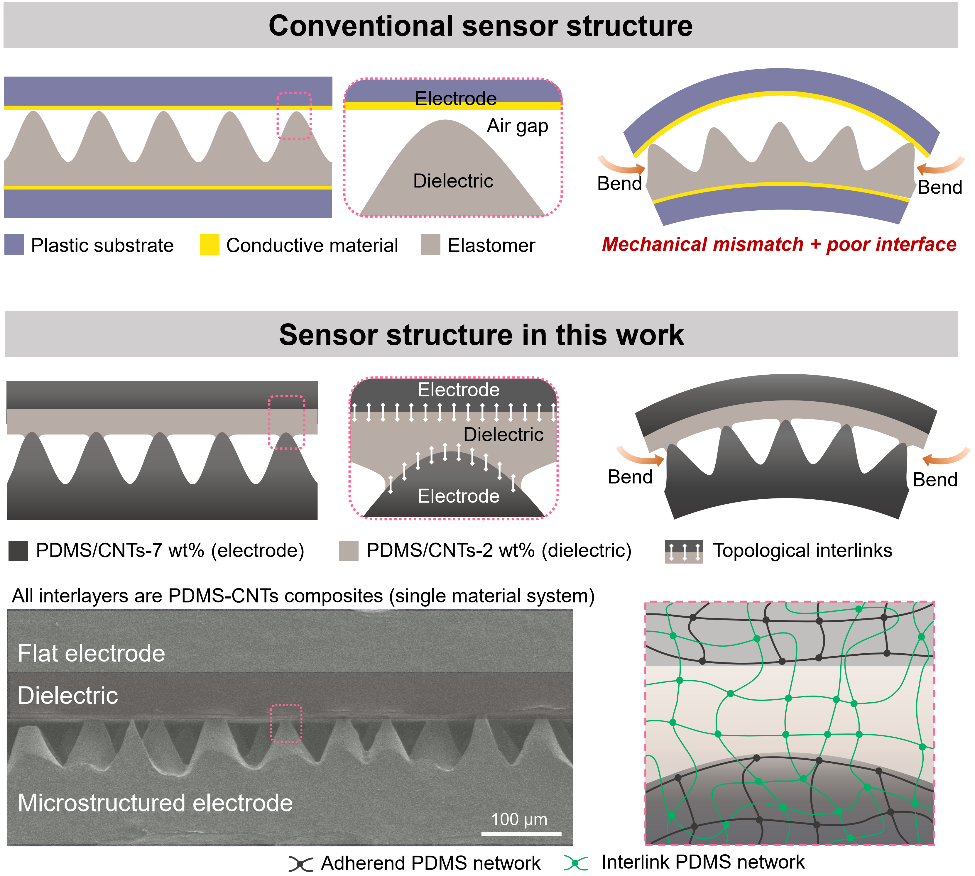

In conventional multilayered e-skins, the functional layers are loosely stacked together without introducing interlayer bonding. As a result, the layers in such devices easily separate or delaminate when imposed to large in-plane compressive stresses or shear stresses. In addition, layers in the device are often made of different materials, which have different rigidities and induce remarkable mechanical mismatch. The significant mechanical mismatch between the electrode and the dielectric in capacitive type e-skins may cause interfacial failure under large deformations.

Prof. Guo’s team sought to find a design that can eliminate or minimize the effect of the mechanical interfaces while maintaining or even further enhancing the sensing properties. They used a single material system with adjustable functions for different interlayers in the sensor and introduced interlinked and microstructured interfaces between them. The microstructured interface with such topological interlinks has a high interfacial toughness of 390 J·m-2 and a shear strength of 90 kPa. The high interfacial toughness stems from the elastic dissipation and discrete rupture of the microstructures. The doping of carbon nanotubes in the soft dielectric layer together with the microstructure design in the sensor also significantly boosts the signal magnitude by a factor of 33.

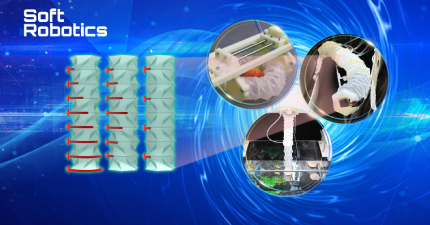

Figure 1. Comparison between conventional e-skins and the sensor structure in this study. Conventional sensors often have a multilayered heterogeneous structure, which easily damages upon deformation. This work presents a sensor structure that has a quasi-homogeneous composition and interlinked interfaces to improve the sensing performance and mechanical stability.

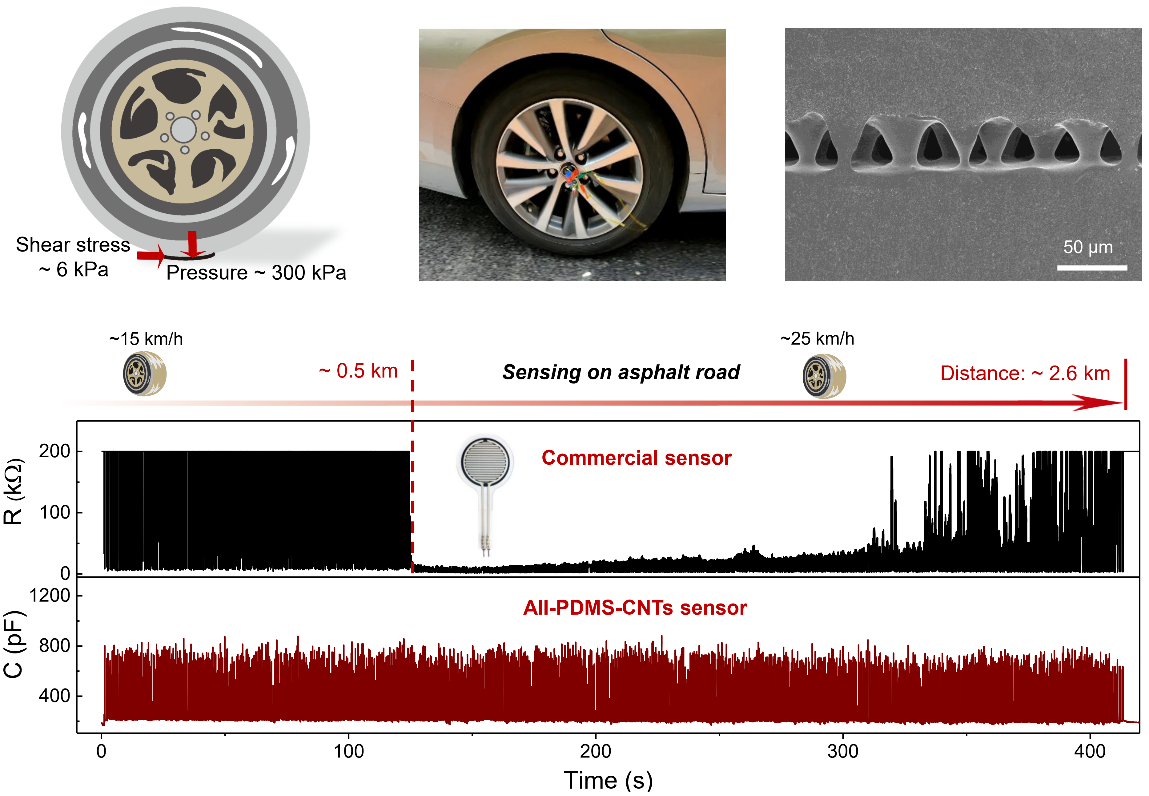

The tough and robust interface enables high fidelity of the sensing signal under harsh mechanical conditions. The sensors exhibit adequate signal stability when subjected to repeated rubbing and shear tests for at least 10,000 cycles or when fixated to the tire tread of a running car driven 2.6 km on an asphalt road.

Figure 2. High stability of the sensor under extreme mechanical conditions.

This study demonstrates that interlinks can also be applied for the seamless integration of a soft robot and sensors for both pressure and strain sensing during gripping tasks without showing any interfacial failure. The sensor can identify various stages during the gripping process via the decoupled bimodal signals of capacitance and resistance. This strategy can be reasonably extended to many other material systems and other types of sensors for attaining robust interfaces and highly stable signals.

Mrs. Yuan Zhang and Dr. Junlong Yang are the co-first authors of this research. Prof. Chuanfei Guo is the corresponding author.

This research was supported by the National Natural Science Foundation of China (NSFC), the Guangdong Innovative and Entrepreneurial Research Team Program, the Shenzhen Science, Technology and Innovation Commission, the Shenzhen Sci-Tech Fund, and the Tencent Robotics X Lab.

Paper link: https://doi.org/10.1038/s41467-022-29093-y

Latest News

Related News