Researchers make new progress in characterization and criteria of phase transformations and lattice slipping in potassium dihydrogen phosphate crystals

Feb 15, 2022

Potassium dihydrogen phosphate (KH2PO4) crystal, referred to as KDP crystal for short, has excellent optical and physical characteristics, so it is widely used in some high-tech fields, especially in the laser ignition system of inertial confinement fusion (ICF).

In order to give full play to the performance of KDP components in the high-energy laser system, it is necessary to avoid all possible types and possible scales of damage on the KDP surface and subsurface in the manufacturing process. However, KDP crystal has the characteristics of low hardness, high brittleness, and extremely sensitive to external temperature and humidity environment, which makes the non-destructive manufacturing of KDP components extremely challenging. This is also an important reason why KDP nondestructive ultra-precision machining has not been realized so far.

Professor Liangchi Zhang’s team from the Institute for Manufacturing Innovation at the Southern University of Science and Technology (SUSTech) recently published a paper entitled “Characterization and criteria of phase transformations and lattice slipping in potassium dihydrogen phosphate crystals” in the Journal of the American Ceramic Society. It is an authoritative journal in the international ceramic field, and this research paper was specially recommended to readers by Wiley.

To reveal the root of the problem, his research team used molecular dynamics as the analysis method. They used the physical potential function for KDP and other materials to deeply study the mechanism of phase transition and slip deformation of KDP before and after external load. The group established the basic structural characterization method to identify micro-nano deformation in KDP and its corresponding trigger state. After research, the important processes such as the initial, stable, and irreversible stages of phase transition, as well as the mechanism of different phase transitions and slips being triggered under different loads, were discovered. These findings provide basic guidance for developing non-destructive intellectual manufacturing technology of ultra-precision KDP components.

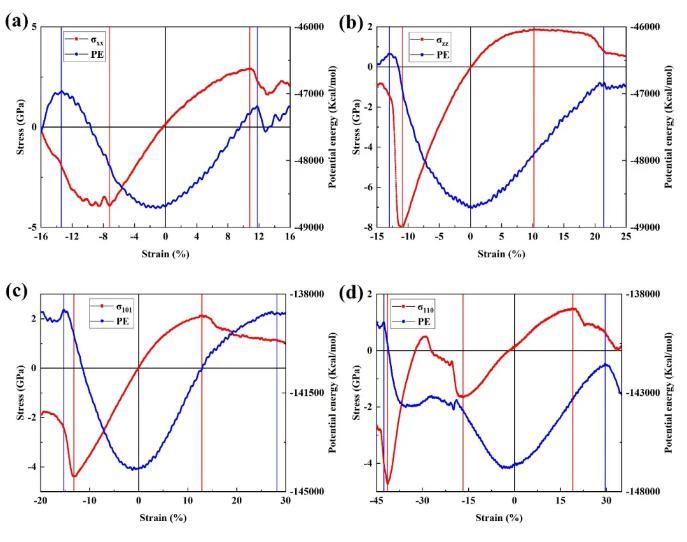

The researchers systematically studied the deformation of KDP crystal under uniaxial tension/compression in four main directions at the deformation rate of 1% per picosecond and the simulation temperature of 300K K. Structural characterization combines two main structural entities of KDP: hydrogen bond and PO4 group, so that all deformed structures can be identified from the original structure by their corresponding parameter ranges. The structural transformation was determined by combining the numerical range with the structural symmetry change.

Figure 1. Stress/energy-strain curves of four crystal directions. (a) <100 > crystal orientation (b) <001 > crystal orientation (c) <101 > crystal orientation (d) <110 > crystal orientation

The chart above (Figure 1) shows the stress/energy-strain curves of KDP under uniaxial tensile/compressive loads with four different main crystal orientations. In these curves, the stress of the material reaches the peak at the red vertical indicator line, which indicates that a phase change/slip is triggered. However, after the total potential energy of the system (blue vertical indicator line) reaches the regional peak, the structural change cannot be recovered. Therefore, various phase transitions and slippage of KDP under loading conditions are determined.

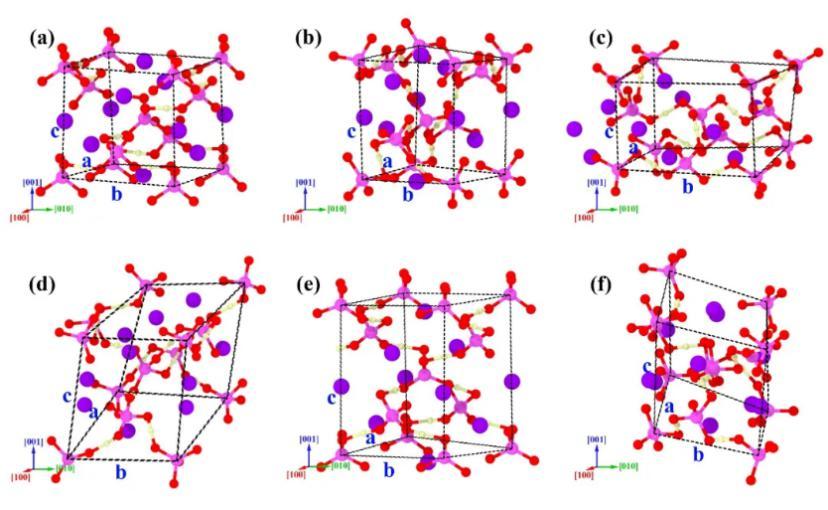

Figure 2. Cell structure of different phase transitions. (a) the original structure (b) orthorhombic phase (c) tetragonal phase (d) triclinic phase (e) monoclinic phase under < 110 > compression (f) monoclinic phase under < 110 > tension

In Figure 2, the cell structure of several phase transitions is found and verified. In contrast, Figure 2a shows the original structure of KDP. In this structure, P atoms and O atoms in KDP are connected by covalent bonds to form tetrahedral PO4 groups. Each PO4 group is connected with the other four adjacent PO4 groups by hydrogen bonds in the direction of the C axis at a distance of c/4. The arrangement of k atoms is the same as that of PO4 groups. Only along the C-axis is it offset by the distance of c/2 from the PO4 group.

Figure 2b is the orthogonal phase. This phase change occurs in the process of stretching and compressing along the < 100 > direction. Figure 2c shows the tetragonal phase, which occurs when compressed in the < 001 > direction. Figure 2d shows the triclinic phase resulting from compression in the < 101 > direction. In this phase transition, PO4 groups are arranged in layers, which are distributed between adjacent layers back to back and face to face. Figures 2e and 2f show the monoclinic phase but have different lattice parameters.

The phase transition shown in Figure 2f results from stretching in the < 110 > direction. In this phase transition, all hydrogen bonds tend to the loading direction, and the arrangement of K atoms is more disordered.

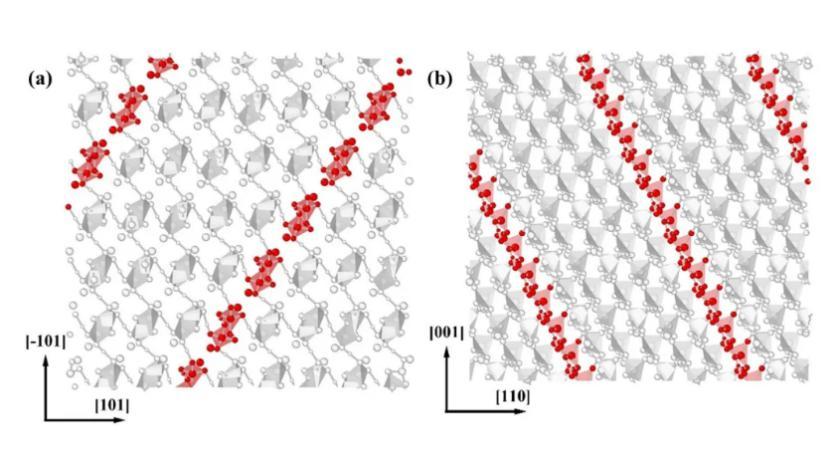

Figure 3. Slip characterized by (a) {100}<010 > slip under < 101 > compression and (b) {112}1/2<111 > slip under < 110 > compression

So far, the research team has found and determined that KDP will trigger a variety of phase transitions and two types of slips under the action of tensile/compressive loads in different directions. The phase transitions remain stable in a relatively low potential energy region. Among these phase transitions, only monoclinic phase transitions generated under uniaxial compression along the < 110 > direction can be stably reversed, and some phase transitions can be triggered under different excitations. The trigger stresses of the two kinds of slips are very close and irreversible. These new findings have important guiding significance for developing non-destructive intellectual manufacturing technology of ultra-precision KDP components.

Shengyao Yang from the School of Mechanical and Manufacturing Engineering at the University of New South Wales (UNSW) is the first author of this paper. Prof. Liangchi Zhang of SUSTech and Zhonghuai Wu of UNSW are the corresponding authors.

This work was supported by the Guangdong Specific Discipline Project and the Shenzhen Key Laboratory of Cross-scale Manufacturing Mechanics Project. This research was also assisted by the resources provided at the NCI National Facility systems through the National Computational Merit Allocation Scheme supported by the Australian Government.

Paper link: https://ceramics.onlinelibrary.wiley.com/doi/10.1111/jace.17955

Related links – Wiley WeChat link: https://mp.weixin.qq.com/s/8UcznbsId0Ox-6Jbdl9BIQ

Latest News

Related News